Artificial Perspiration, Artificial Saliva, Artificial Urine, Synthetic Blood, and other Artificial Body Fluid Products Made for Laboratory Testing

Pickering Laboratories’ Artificial Perspiration, Artificial Saliva, Artificial Urine, Synthetic Blood, and other Artificial Body Fluids products are made to official product testing specifications from ANSI, NIST and other official standards organizations and are used worldwide for product testing and research applications. Our expert manufacturing processes and quality control standards enables excellent batch reproducibility and precise matching of official formulations.

Custom formulations are routinely produced with the same guarantee of precision and reproducibility. more

Perspiration Tests of Consumer Products

By Michael Pickering, Ph.D., Pickering Laboratories

Testing laboratories are essential to economic growth. A rapidly developing global economy requires reproducibility. Eccrine perspiration can react with consumer products to cause health problem and reduce service life. More

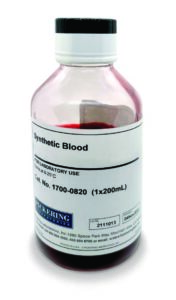

Synthetic Blood Solutions

By Pickering Laboratories

Pickering Laboratories’ synthetic blood formulations are prepared according to official methods ASTM F1819-07, ASTM F1670, ASTM F1862 and ASTM F2100. They are intended for product testing and have the surface tension and viscosity close to human blood. More

Testing Solutions for:

- Personal and Wearable Electronics

- Watch-cases and accessories

- Colorfastness to light for fabric

- Colorfastness to perspiration for leather

- Sweat for Ophthalmic optics

- Dental metal alloys

- Colorfastness of products taken orally

Perspiration Tests of Consumer Products

By Michael Pickering, Ph.D., Pickering Laboratories

Testing laboratories are essential to economic growth. A rapidly developing global economy requires reproducibility. Eccrine perspiration can react with consumer products to cause health problem and reduce service life. More

Artificial Perspiration Assures Reproducible Testing

By Michael Gottschalk, Pickering Laboratories

Pickering Laboratories announced immediate availability of its newly formulated line of artificial eccrine perspiration. More

Testing Solutions for:

- Personal and Wearable Electronics

- Watch-cases and accessories

- Colorfastness to light for fabric

- Colorfastness to perspiration for leather

- Sweat for Ophthalmic optics

- Dental metal alloys

- Colorfastness of products taken orally